Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LJ-10

Brand: SIHAI

Certification: ISO

Warranty: 1 Year

Service Life: <15 Years

Voltage: 380V

Structure: Horizontal

Cooling: Water Cooling

Power: 15.5KW

Pressure: Atmospheric

Heating Method: Directly

Installation: Foundation

Working Form: Batch

Reactor Size: 2200*6000 Mm

24 Hours Oil Output: 2.5-3.2 Tons Fuel Oil

24 Hours Processing Capacity: 6-8 Tons Raw Material

Weight Of Reactor: 26 Tons

Packaging: Seaworthy packing 2*40HQ

Productivity: 200 sets per year

Transportation: Ocean,Land

Place of Origin: Henan

Supply Ability: 200 sets per year

Certificate: CE ISO

HS Code: 8419409090

Port: Lianyungang,Qingdao

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CIF

About us:

Our company is located in Chenfeng Avenue, Pingtai Economical Development Zone, Shangqiu, Henan, China. It covers an area of 75,000 square meters, of which there are two modern production workshops cover an area of 60,000 square meters. Our company mainly engaged in waste rubber, waste plastics, waste tires, waste aluninum foil, waste mineral oil and other environmental pyrolysis equipment, distillation equipment and peripheral ancillary equipment processing production and sales. Company annual output is more than 400 sets of environmental protection equipment. Our products have been exported to Europe and the United States, South Africa, Southeast Asia, the Middle East and the Mainland and other 36 countries and regions.

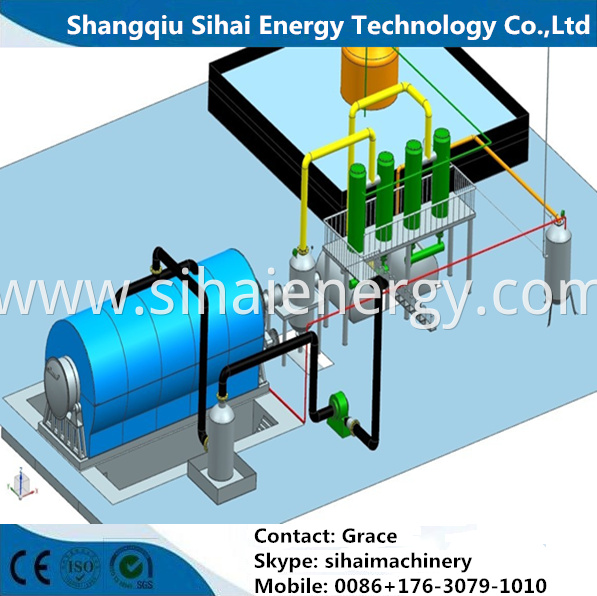

Working process of the Scrap Tire Recyle To Diesel :

1.Feeding requires 1-2 hours. Tires less than 1.4 meters can be directly fed into the tire. Large tires need to be cut and then fed; plastics are fed by automatic feeders or conveyor belts;

2. Heating takes about 6-8 hours. Normally, oil and gas will be produced when heated to 180 degrees. At 240-260 degrees, oil and gas will be produced in large quantities.

3. Cooling, oil and gas condenses into fuel oil through the cooling system;

4. During the pyrolysis and recovery of exhaust gas, in addition to oil and gas, some flammable but non-condensable gases will be generated. We call this [exhaust gas." This gas can be directly recovered for heating the pyrolysis reactor to save energy. fuel;

5. Carbon black and steel wire slagging, the end of the cracking process, oil and gas out of the reactor, the need to discharge the reactor inside the residual material, to carry out a new cracking process, these residues mainly include carbon black and steel wire used to make tire plastic.

Safety of the Scrap Tire Recyle To Diesel :

The main equipment is of high safety. The phase of the unliquefizable waste gas produced during the process is alkyl from C1 to C4, which is dangerous when burning directly. In our process, it is transferred first through a water seal device and a safety device- burning air muzzle. Before burning, we should ensure the safety of production.

Environmental of the Scrap Tire Recyle To Diesel :

Dispose waste gas, liquid, and residua in the process:

a. Waste gas: Transferred through two safety device: water seal &burning air nozzle. Fully burnt, not only eliminated pollutant but also minimized the quantity of fuels. For smoke dust discharge, we apply series machines of patent in our company Desulphurization and dust remover which could control the smoke dust discharge amount meet relative standards of GB-2001.

b. Waste liquid: Produced waste acidic water in the process of oil disposing (50kg process from 1 ton of oil easy to process for small quantity). counteract the liquid by alkalescent liquid solution. After three stage of filtration, the litmusless wa ste water was introduced to evaporator(use the heat of the flue of main processor as its heating resource)

c. Waste solid. The solid residua will be left after the catalyst splitting from scrap plastic, approximately composes the waste plastic weight about 5% to 10%. Its main component is the thick black carbon. It can be the raw material of the production industry of black carbon. Also could be mixed with the pulverized coal ash which produces for the raw material thermal power plant, also could be the raw material of manufacture pulverized coal ash brick (one kind of environmental protection building material).

Main components of the Scrap Tire Recyle To Diesel :

Product Categories : Waste Tire Pyrolysis Plant

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.