Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LJ-9

Brand: SIHAI

Warranty: 1 Year

Certification: Other

Service Life: <15 Years

Voltage: 380V

Structure: Horizontal

Cooling: Water Cooling

Pressure: Atmospheric

Heating Method: Directly

Working Form: Batch

Reactor Size: 2200*6600 Mm

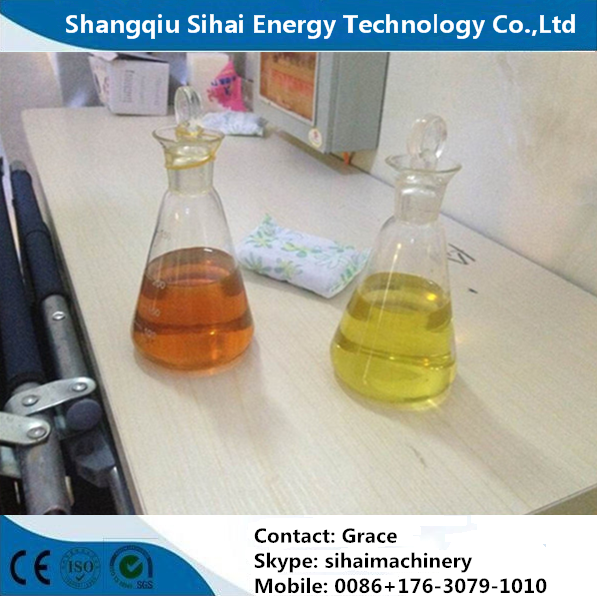

24 Hours Oil Output: 3.2-4.5 Tons Fuel Oil

Weight Of Reactor: 29 Tons

24 Hours Processing Capacity: 8-10 Tons Raw Material

Installation: Free Of Charge

Packaging: Seaworthy packing 2*40HQ

Productivity: 200 sets per year

Transportation: Ocean,Land

Place of Origin: Henan

Supply Ability: 200 sets per year

Certificate: CE ISO

HS Code: 8419409090

Port: Lianyungang,Qingdao

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CIF

About us:

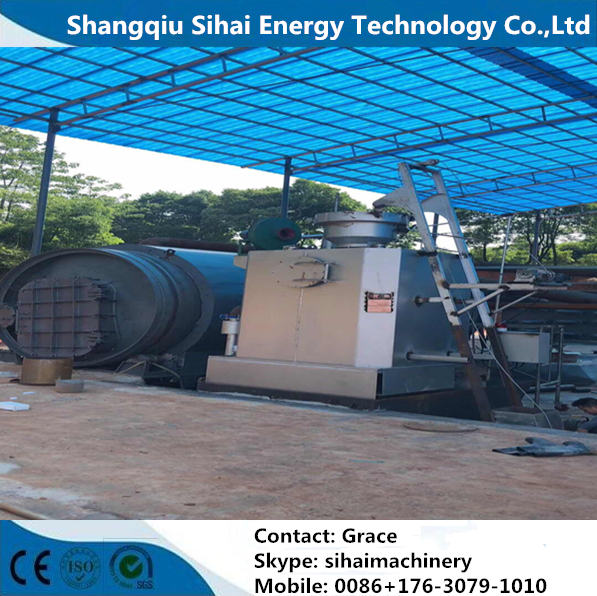

Our company is located in Chenfeng Avenue, Pingtai Economical Development Zone, Shangqiu, Henan, China. It covers an area of 75,000 square meters, of which there are two modern production workshops cover an area of 60,000 square meters. Our company mainly engaged in waste rubber, waste plastics, waste tires, waste aluninum foil, waste mineral oil and other environmental pyrolysis equipment, distillation equipment and peripheral ancillary equipment processing production and sales. Company annual output is more than 200 sets of environmental protection equipment. Our products have been exported to Europe and the United States, South Africa, Southeast Asia, the Middle East and the Mainland and other 36 countries and regions.

Features of Refine Waste PP Plastic To Oil Equipment :

a. In the design of pyrolysis key device, completely overcome the local heat uneven, easy to break, low yield, short life and other unfavorable factors of the current vertical flat bottom Pyrolysis Plant.

b. With fast and practical feed and slag system.

c. Efficient gas heating system. In the process of refining, when the heated gas reaches 150 degrees Celsius, it will produce a lot of gas which can not be liquefied in normal temperature and pressure methane to butane.These gases are fully burned by specially designed gas nozzles, will produce a lot of energy which greatly saves energy.

d.Flue dust removal system has a desulfurization dust cather(qualified), equipped with two ways water impact cyclone dust removal chamber, which can ensure the discharge of flue outlet reach safe discharge standard.

Technical Parameters of Refine Waste PP Plastic To Oil Equipment :

Model:LJ-9

Raw material:Waste tire, waste plastic, waste rubber

Structure:Horizontal

24hours processing capacity:8-10tons raw materials

24hours oil output:3.2-4.5tons fuel oil

Work pressure:Atmospheric

Host speed:0.4r\min

Power:15.5KW

Cooling:Water cooling

Lose water(T\H):8

Transport:External gear drive

Heating method:Directly

Installation:Foundation

Noise dB(A):≤85

Reactor size length*wideth:2200x6600

Working form:batch

Weight of Reactor(T):29

Manufacuring time:20days

Layout of Refine Waste PP Plastic To Oil Equipment :

Treatment of the raw material

↓

Hydraulic automatic feeding in

↓

Automatic slag-out ← pyrolyzer → desulphurization and deduster

↓ ↓

Air package draft fan

↓ ↓

1st tube condenser first 2nd purifier

↓ ↓

2nd tube condenser second 2nd purifier

↓ ↓

Cooling tower ← calandria condenser emission reach the standard

↓

Oil and gas separator product oil

↓

Water seal explosion-proof machine

Product Categories : Waste Plastic Pyrolysis Plant

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.